A marine bulkhead, also referred to as a seawall, or retaining wall, is a man-made structure constructed along a shoreline for the purpose of controlling erosion. We specialize building wood and vinyl bulkheads for both residential and commercial projects.

With 65 years of Marine Construction experience, we build precise, durable structures using top quality materials and superior craftsmanship. We work closely with our clients from beginning to completion of each project. We assist in getting the necessary permits from the State of Texas, The Army Corps of Engineers and any city permitting if required.

Wood or Vinyl? This is a common question we get asked time and time again. While wood is least expensive, it will not last as long as a vinyl wall . Wood will give a natural look and because we use treated materials, its protected from harmful UV rays and marine borers. A vinyl wall is more expensive but will last longer, easy to install, corrosion resistant, UV resistant, impervious to marine borer damage, zero toxic coatings, wont rust and gives an aesthetic appeal.

Bulkhead Construction

Treated Pilings – For pilings submerged in salt water, brackish water and subject to marine borer attacks, we use 2.5 cca treated materials. Chromated Copper Arsenate or cca is pressure treatment process which penetrates the cells of the wood, making it resistant to marine borers, termites and UV rays.

For pilings submerged in fresh water, we use .60 cca treated materials.

After evaluating your project, we will determine the size of pilings needed for your project. The length, butt ( diameter of the piling), and the depth at which they should be driven in to the ground is a per job basis. We have used Building Products Plus for many years as our trusted material supplier

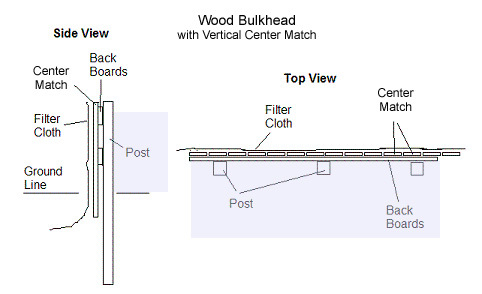

Walers – Walers are treated timbers that reinforce the entire bulkhead and to keep it straight. One is positioned in front and the other in back on the wall. The number of walers needed is determined per job.

Top Cap – Boards that cover the top of the bulkhead along its length.

Tie Back System – Prevents the bulkhead from collapsing forward, consisting of anchor components placed behind the wall and a tie back component to attach the wall to the anchor.

Deadman System – “Deadman” consists of treated wood posts, buried below the ground behind the bulkhead and connected to the wall with galvanized tie rods.

Tie Rods – We use galvanized tie rods and bolts on each project.

Geotextile Filter Cloth – Geotextiles act as a filter to help prevent subsurface soil migration. We use filter cloth on bulkheads as well as when placing Rip Rap.

Sheathing – Sheathing is applied to strengthen the structure.

Give us a call today @ 281.339.1561 to discuss your upcoming project!